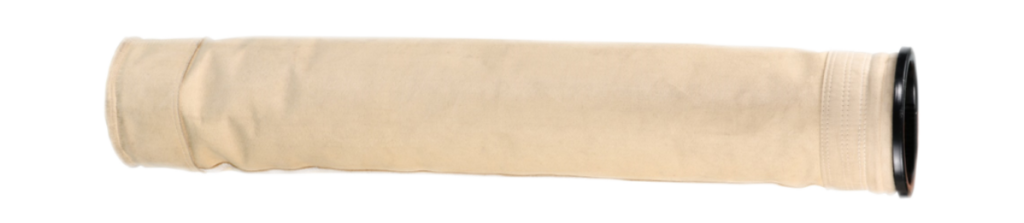

As industrial pollution intensifies and calls for environmental protection amplify, various dust filtration materials are increasingly utilized in production and manufacturing sectors. Among these, PPS (polyphenylene sulfide) dust filter bags stand out as premium filtration materials, boasting high-temperature resistance, corrosion resistance, and oxidation resistance. Their unique properties make them widely applicable in filtering and separating various liquid and gaseous media, finding extensive use in the following sectors.

1. Steel Industry

PPS dust filter bags play a pivotal role in the steel industry. The steel production process generates high-temperature, high-humidity, and high-concentration industrial dust and exhaust gases, posing significant demands on filtration materials. PPS dust filter bags can withstand these harsh conditions, maintaining stable filtration performance and effectively capturing and removing particulate matter, thereby protecting the environment and ensuring the normal operation of production equipment.

2. Cement Industry

The cement industry is another major application field for PPS dust filter bags. The production process in cement manufacturing generates high-temperature flue gases and dust, challenging the performance of filtration materials. PPS dust filter bags, with their excellent high-temperature performance and chemical stability, can maintain stable filtration effects under these conditions, providing a clean and efficient production environment for cement manufacturing.

3. Boilers and Metallurgical Industry

Boiler combustion processes generate various flue gases and ash. Without proper dust removal treatment, these emissions can pollute the environment. In this context, PPS dust filter bags can effectively capture dust and impurities in high-temperature, high-pressure, acidic, and alkaline environments, ensuring efficient boiler operation. During industrial and metallurgical production, large amounts of dust and impurities are produced, posing significant threats to human health and the environment. PPS dust filter bags can effectively mitigate these issues, reducing environmental pollution and health hazards for workers.

4. Cement and Ceramics Industry

During the production of cement, ceramics, and similar industries, substantial amounts of aerosol particles are produced. If directly released into the atmosphere, they can adversely affect the environment and human health. Using PPS dust filter bags to treat industrial waste gases and dust can significantly reduce particle concentrations and dust emissions, ensuring environmental protection and safety during industrial production.

5. Pharmaceutical and Food Industry

In the pharmaceutical and food processing sectors, filtering and cleaning the air of bacteria, viruses, and tiny particles like sawdust is essential. Without suitable filtration materials and equipment, product quality and hygiene can be severely impacted. PPS dust filter bags can ensure air purity and a hygienic manufacturing environment, minimizing health risks.

6. Agriculture and Fisheries Industry

During agricultural and fisheries production, large amounts of ammonia and hydrogen sulfide gases are produced. If not promptly treated, these odorous gases can negatively impact workers and the surrounding environment. Using PPS dust filter bags for gas deodorization can reduce odors and purify the air, promoting the growth of crops and animals.

PPS dust filter bags are not only suitable for environmental protection but also have wide applications across various industries, making them a promising high-performance filtration material. As technology and production processes advance, the demand for PPS dust filter bags will gradually increase, making them an indispensable part of environmental protection and manufacturing. Therefore, all sectors should prioritize using PPS dust filter bags for environmental management and waste gas treatment, collectively creating clean, hygienic, and healthy production environments.

When selecting PPS dust filter bag suppliers and manufacturers, attention should be given to product quality and performance, considering aspects like price and after-sales service. Only by choosing regular, professional manufacturers can one ensure that the purchased PPS dust filter bags provide excellent filtration effects and long-term stable performance.

PPS dust filter bags have a wide range of applicability, suitable for boilers, metallurgy, cement, ceramics, pharmaceuticals, food, agriculture, fisheries, and many other industries and fields. They are essential environmental protection equipment and materials, playing a crucial role in protecting the environment and human health. It is hoped that all industries recognize the importance of environmental protection, actively taking measures to jointly build clean, beautiful production and living environments.